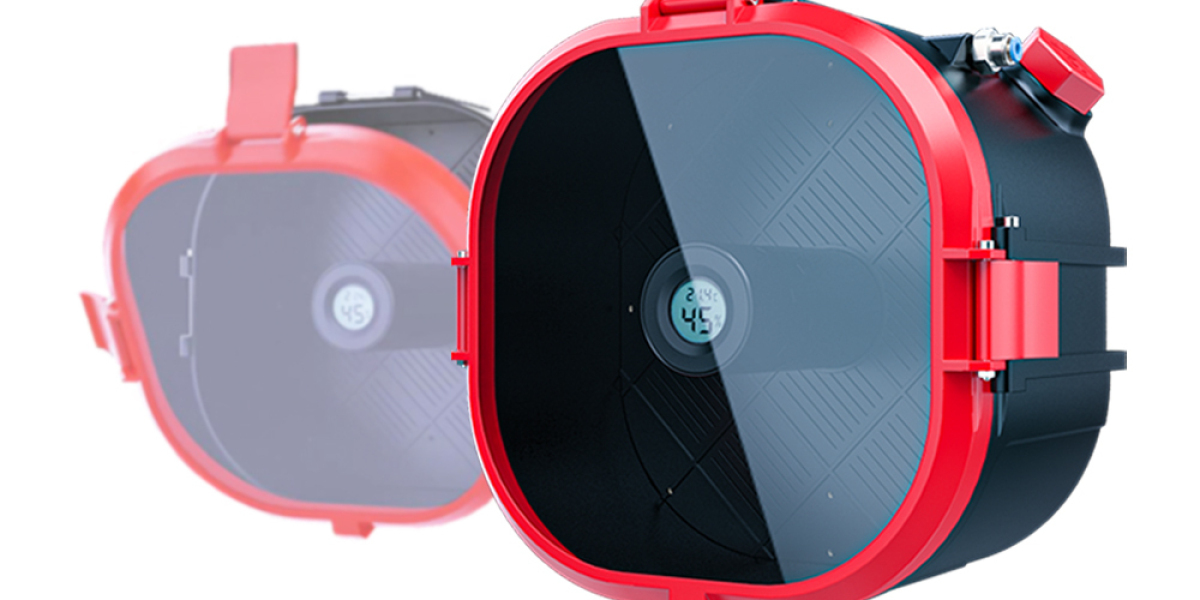

In order to ensure the safe use of equipment and extend its service life, operators need to understand and follow a series of precautions. This article will detail the key points to pay attention to when using the filament dry box.

Power supply and grounding:

Before use, ensure that the power supply voltage meets the device requirements. The power socket of the drying oven must be well grounded to prevent electric shock accidents. Ensure that the power supply line is equipped with sufficient on/off switches and fuses.

Place environment:

The drying box should be placed in a dry, horizontal place indoors, avoid being near the environment containing acid, alkali and other corrosive substances. Leave a certain space around the device to facilitate heat dissipation and maintenance.

Item placement:

The items placed in the drying box should not be too much or too crowded, and enough space should be left to ensure air circulation. Avoid placing items on the heat sink at the bottom of the studio to prevent overheating damage.

Flammable and explosive items:

It is strictly forbidden to put inflammable, explosive and volatile items into the drying box to prevent fire or explosion accidents.

Operation and observation:

When powered on, do not touch the electrical parts in the chassis with your hands or wipe with a damp cloth. When the items in the box need to be observed, they can be observed through the glass door to minimize the number of times they are opened, so as not to affect the constant temperature.

Temperature control:

After the equipment is used for the first time or is not used for a long time, the error between the measured temperature and the actual temperature in the working room should be checked to ensure the temperature control accuracy. When the temperature is close to the set temperature, the heating indicator may be on and off, which is a normal phenomenon.

Maintenance and cleaning:

The silver contact of the temperature regulator should be checked regularly for smoothness, and if necessary, polished with fine gauze. If the device is not used for a long time, cut off the power supply, cover it with a dust cover, and store it in a dry environment.

Troubleshooting:

If the device indicator light is not on or the temperature control is faulty, check whether the lamp, circuit, relay and other components are damaged. The power supply must be cut off during maintenance.

Blower use:

When the drying box is working, the blower switch must be turned on to make it run to ensure that the temperature in the box is uniform. Avoid running the blower continuously for a long time, and take proper rest to extend its service life.

By following the above considerations, operators can ensure the safe and efficient operation of the filament drying enclosure while extending the service life of the equipment. In the process of use, if you encounter any problems or abnormal conditions, you should immediately cut off the power supply, and contact professional technicians for inspection and maintenance.