In modern industrial production, machine protection is an important link to ensure production safety, improve the service life of equipment and protect the health of workers. As a new type of material, PETG filament shows a broad application prospect in the field of machine protection with its unique properties.

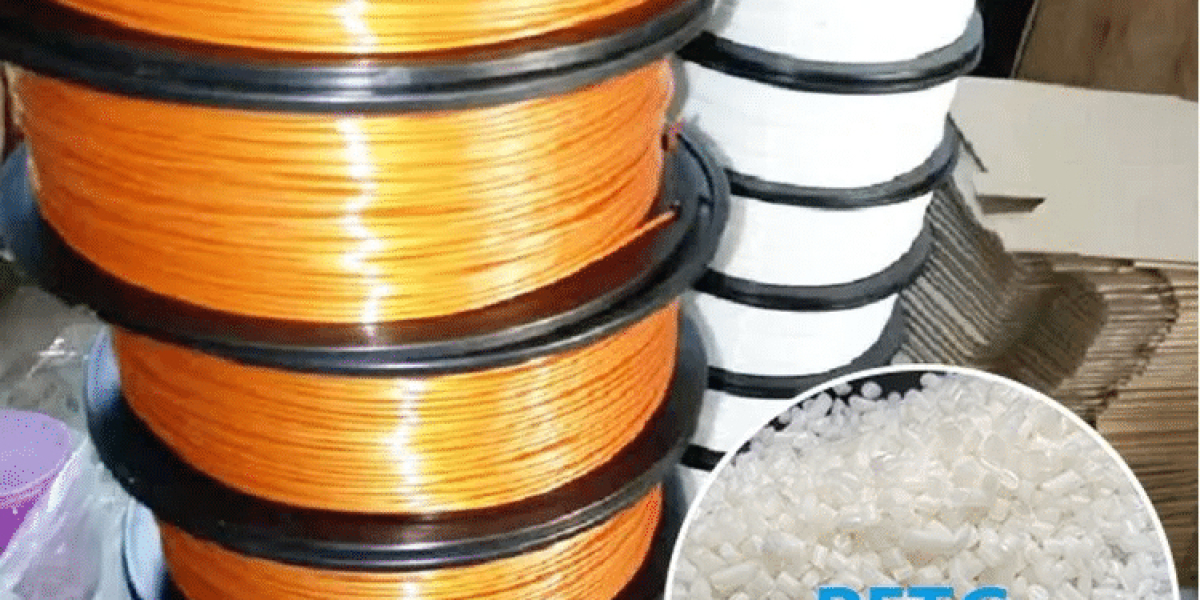

PETG (polyethylene terephthalate 1, 4-cyclohexane dimethyl ester) filament is a thermoplastic material made by 3D printing technology. It combines the advantages of PET (polyethylene terephthalate) and PCT (polybutylene terephthalate), with high strength, high toughness, good chemical resistance and thermal stability. These characteristics give PETG filaments a significant advantage in the field of machine protection.

First, PETG filaments perform well in making machine protection components such as shields and nets. Traditional metal protective parts, although strong, are heavier and more inconvenient to install and maintain. The protective parts made of PETG filament are light in weight and high in strength, which can reduce the burden on the machine and improve production efficiency while ensuring the protective effect. In addition, PETG material has a good transparency, can be made into a transparent or translucent protective cover, convenient for operators to observe the running state of the machine, timely detection and treatment of problems.

Second, PETG filaments are also widely used in making machine parts. For example, PETG filaments can replace traditional metal or plastic parts in situations where large impact forces are required. Its high toughness and impact resistance effectively absorb impact forces and reduce the risk of machine damage. At the same time, PETG materials have good wear resistance and chemical corrosion resistance, which can maintain stable performance in harsh environments and extend the service life of parts.

In addition, PETG filaments can be used to make seals and gaskets for machines. During the operation of the machine, seals and gaskets play a role in preventing leakage, shock absorption and sound insulation. PETG material has good elasticity and sealing performance, which can meet the sealing needs of different machine parts. At the same time, its chemical corrosion resistance makes PETG seals and gaskets in contact with oil, chemicals and other media are not easy to age, deformation, to ensure the normal operation of the machine.

In terms of environmental protection, PETG filaments also have significant advantages. The energy consumption in the production process is low, and the materials can be recycled, which meets the requirements of modern industrial production for environmental protection and sustainable development. Machine protection components made from PETG filament not only increase production efficiency, but also reduce resource waste and environmental pollution.

In short, PETG filament, as a new material, has a wide range of application prospects in the field of machine protection. Its high strength, high toughness, good chemical resistance and thermal stability make PETG filaments excellent in the production of shields, shields, components, seals and gaskets. With the continuous development and popularization of 3D printing technology, the application of PETG filament in the field of machine protection will be more extensive, bringing more convenience and benefits to industrial production.