In recent years, the emergence of large 3D printers has significantly transformed the landscape of manufacturing. These advanced machines are not only enhancing production capabilities but also redefining the way industries approach design and prototyping. But what exactly makes large 3D printers so revolutionary?

Understanding Large 3D Printers

A large 3D printer is designed to create substantial objects through additive manufacturing processes. Unlike traditional manufacturing methods, which often involve subtracting material from a larger block, 3D printing builds objects layer by layer. This method allows for greater design flexibility and the ability to produce complex geometries that would be impossible or cost-prohibitive with conventional techniques.

Key Advantages of Large 3D Printers

- Cost Efficiency: Large 3D printers can significantly reduce material waste, leading to lower production costs.

- Customization: They enable the production of tailored solutions, catering to specific customer needs.

- Speed: Rapid prototyping capabilities allow for quicker turnaround times in product development.

- Complex Designs: The ability to create intricate designs opens new avenues for innovation.

Applications Across Industries

Large 3D printers are making waves across various sectors, including aerospace, automotive, and healthcare. For instance, in the aerospace industry, companies are utilizing these printers to produce lightweight components that enhance fuel efficiency. In healthcare, large 3D printers are being used to create custom prosthetics and implants, improving patient outcomes.

Challenges and Considerations

While the benefits of large 3D printers are substantial, there are challenges to consider. The initial investment in these machines can be significant, and businesses must also invest in training personnel to operate them effectively. Additionally, ensuring quality control and material compatibility is crucial for successful implementation.

Future Trends in Large 3D Printing

As technology continues to advance, the future of large 3D printers looks promising. Innovations such as multi-material printing and improved software for design optimization are on the horizon. These advancements will likely enhance the capabilities of large 3D printers, making them even more integral to modern manufacturing.

Conclusion: Embracing the Change

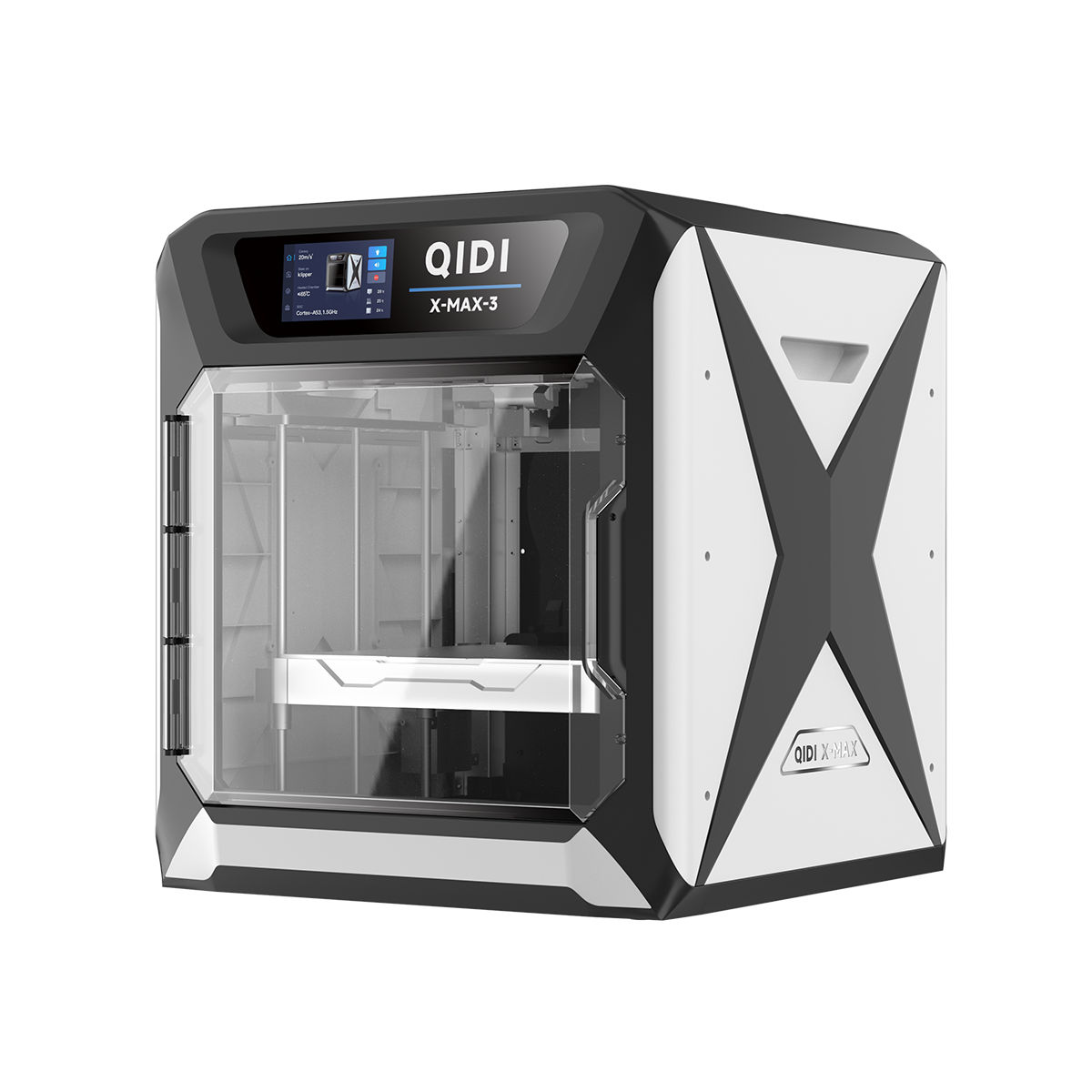

In conclusion, large 3D printers are not just a trend; they represent a fundamental shift in how products are designed and manufactured. By embracing this technology, industries can unlock new levels of efficiency and creativity. If you are interested in exploring the capabilities of large 3D printers, consider checking out the  for a high-quality solution that meets your needs.

for a high-quality solution that meets your needs.