California, known as the global hub for innovation, is home to cutting-edge industries such as aerospace, semiconductors, and telecommunications. One of the pivotal technologies fueling these industries is the co-axial blade probe, a critical tool for ensuring precision and efficiency in testing and assembly processes. In this article, we’ll delve into what co-axial blade probes are, their importance, and how they’re revolutionizing industries in California.

What is a Co-Axial Blade Probe?

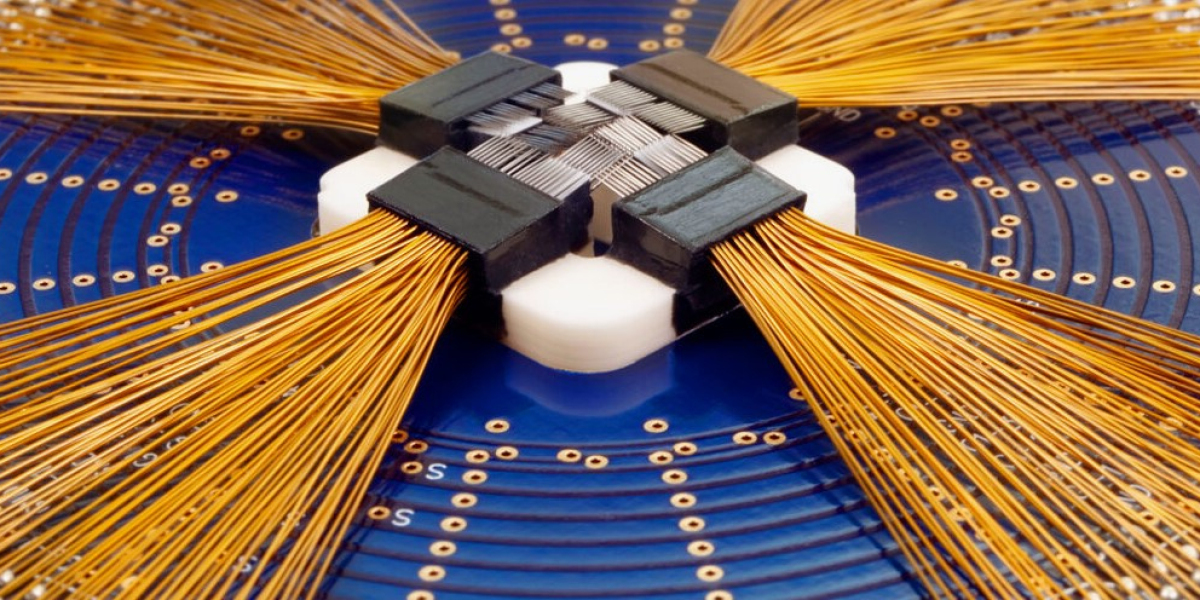

A co-axial blade probe is a high-precision testing device designed to measure and inspect electrical and mechanical components. Unlike standard probes, its co-axial structure ensures minimal signal interference, enabling accurate readings in complex systems. These probes are commonly used in industries where testing precision is paramount, such as aerospace, medical devices, and semiconductors.

Why Co-Axial Blade Probes Are Essential in Advanced Industries

1. Unmatched Testing Accuracy

Co-axial blade probes are engineered to deliver precise and repeatable measurements, ensuring that even the smallest flaws are detected. This level of accuracy is essential for industries that cannot afford errors, such as aircraft manufacturing and medical equipment production.

2. Reducing Signal Interference

Thanks to their unique co-axial design, these probes reduce electromagnetic interference (EMI) and other forms of noise, making them ideal for testing high-frequency circuits and delicate electronic components.

Key Features of Co-Axial Blade Probes

1. High-Frequency Compatibility

These probes are optimized to handle high-frequency signals, which is crucial for industries like telecommunications and radar systems. Their ability to test at such frequencies ensures seamless operation of advanced technologies.

2. Durability and Longevity

Made with high-grade materials, co-axial blade probes are built to withstand repeated usage without compromising on accuracy. This durability makes them cost-effective for businesses over the long term.

3. Customizable Design

Many manufacturers in California offer customized co-axial blade probes to suit specific testing needs. Whether it's a unique shape or a specific range of frequencies, customization options enhance their versatility.

Applications of Co-Axial Blade Probes in California Industries

1. Semiconductor Testing

California’s booming semiconductor industry relies heavily on co-axial blade probes for wafer testing and quality assurance. These probes ensure that each chip meets stringent performance standards.

2. Aerospace Engineering

In the aerospace sector, these probes are indispensable for testing avionics systems, navigation circuits, and communication modules, ensuring that every component is mission-ready.

3. Medical Device Manufacturing

From pacemakers to advanced imaging equipment, medical device manufacturers use co-axial blade probes to guarantee product reliability and patient safety.

4. Automotive Industry

As California leads the charge in electric vehicle (EV) innovation, co-axial blade probes are essential for testing battery systems, sensors, and onboard computers in EVs.

How California Companies Leverage Co-Axial Blade Probes

1. Cutting-Edge Research and Development

California's tech ecosystem thrives on constant innovation. Co-axial blade probes are a key part of R&D labs, enabling precise data collection during prototype development.

2. Quality Assurance Processes

Companies in California prioritize quality, using co-axial blade probes in their final inspection stages to ensure products meet regulatory standards and customer expectations.

3. Integration with Automated Systems

Modern manufacturing facilities in California integrate co-axial blade probes with automated testing systems, reducing human error and speeding up production cycles.

Leading Manufacturers of Co-Axial Blade Probes in California

1. ProbeTech Solutions

Based in Silicon Valley, ProbeTech Solutions specializes in designing and producing custom co-axial blade probes for semiconductor and telecommunications industries.

2. Precision Instruments Co.

This Los Angeles-based company is renowned for its high-quality testing probes, catering to aerospace and medical device manufacturers across California.

3. Innovate Test Systems

Located in San Diego, Innovate Test Systems provides advanced co-axial probe solutions, focusing on high-frequency applications and durability.

Advantages of Using Co-Axial Blade Probes

1. Enhanced Product Reliability

By using co-axial blade probes, manufacturers can ensure their products are free from defects, leading to increased customer satisfaction and brand loyalty.

2. Cost-Effective Testing

Although the initial investment might be higher, the durability and accuracy of these probes result in long-term savings by reducing waste and improving yield rates.

3. Meeting Industry Standards

Co-axial blade probes help companies comply with stringent industry regulations, minimizing the risk of recalls or legal penalties.

Challenges in Adopting Co-Axial Blade Probes

1. High Initial Costs

While the benefits outweigh the costs, the initial expense of acquiring high-quality probes can be a hurdle for smaller businesses.

2. Specialized Training

Using co-axial blade probes requires specialized knowledge, which means additional training for staff. However, this can be seen as an investment in workforce development.

Future of Co-Axial Blade Probes in California

As technology continues to advance, the demand for more precise testing tools will only grow. Innovations in material science and signal processing are expected to make co-axial blade probes even more efficient, ensuring California remains at the forefront of global technological progress.

Tips for Choosing the Right Co-Axial Blade Probe

1. Define Your Testing Needs

Consider the specific requirements of your application, such as frequency range and durability, before selecting a probe.

2. Opt for Customization

Choose a manufacturer that offers customized solutions to meet your unique needs, ensuring optimal performance.

3. Check Compatibility

Ensure the co-axial blade probe is compatible with your testing equipment, avoiding potential integration issues.

Conclusion

Co-axial blade probes play a crucial role in driving precision, reliability, and efficiency across California’s advanced industries. From semiconductors to aerospace, these probes are indispensable tools for innovation and quality assurance. As demand grows and technology evolves, co-axial blade probes will continue to empower California’s industries to set new standards in excellence. For businesses seeking top-notch performance and durability, investing in co-axial blade probes is a strategic move toward staying competitive in today’s fast-paced world.