When it comes to 3D printing, the choice of filament can significantly impact the quality and durability of the final product. Among the various materials available, ABS filament for mechanical parts stands out due to its unique properties. This article delves into the advantages of using ABS filament, particularly for creating robust mechanical components.

Understanding ABS Filament

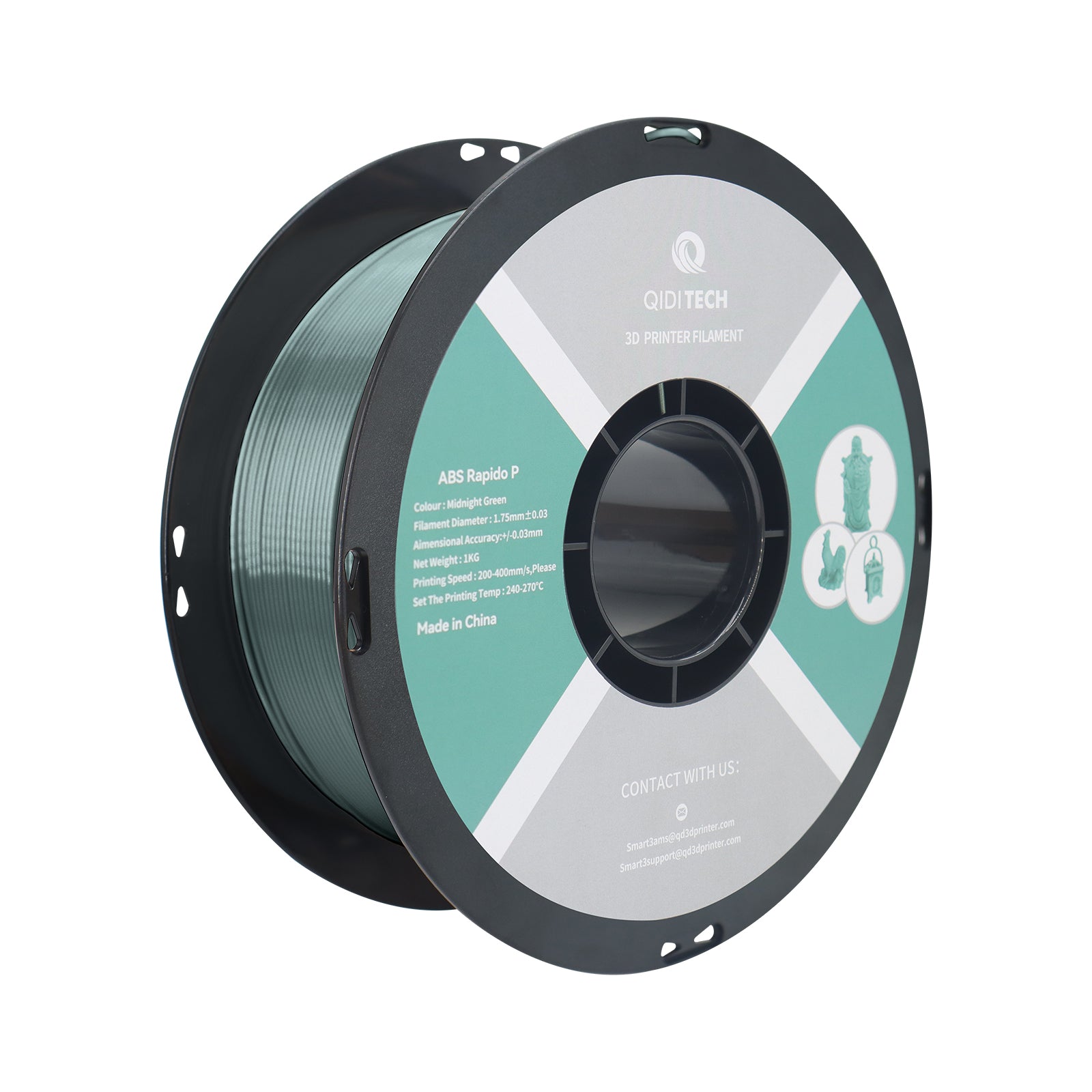

ABS, or Acrylonitrile Butadiene Styrene, is a thermoplastic polymer known for its strength and resilience. It is widely used in various industries, including automotive, consumer goods, and electronics. But why is ABS filament particularly favored for mechanical parts? The answer lies in its exceptional characteristics:

- High Impact Resistance: ABS filament can withstand significant stress and impact, making it ideal for parts that experience mechanical loads.

- Temperature Resistance: With a glass transition temperature of around 105°C, ABS maintains its shape and integrity under heat.

- Ease of Post-Processing: ABS can be easily sanded, painted, or glued, allowing for a polished finish on mechanical parts.

Applications of ABS Filament in Mechanical Parts

The versatility of ABS filament for mechanical parts allows it to be used in a variety of applications. Some common uses include:

- Automotive Components: ABS is often used for dashboard parts, housings, and other interior components due to its durability.

- Consumer Electronics: Many electronic devices feature ABS parts, ensuring they can withstand daily wear and tear.

- Industrial Equipment: ABS is suitable for creating prototypes and functional parts in machinery, thanks to its strength and reliability.

Benefits of Using ABS Filament for Mechanical Parts

Choosing ABS filament for mechanical parts offers several benefits that enhance the overall quality of 3D printed items:

- Cost-Effectiveness: ABS is generally more affordable than other high-performance materials, making it accessible for various projects.

- Availability: This filament is widely available in numerous colors and formulations, providing options for customization.

- Strong Layer Adhesion: ABS exhibits excellent layer bonding, which is crucial for the structural integrity of mechanical parts.

Conclusion

In summary, ABS filament for mechanical parts is an excellent choice for those seeking durability and reliability in their 3D printed components. Its unique properties, coupled with its versatility, make it suitable for a wide range of applications. If you are interested in exploring high-quality ABS options, consider checking out for your next project.