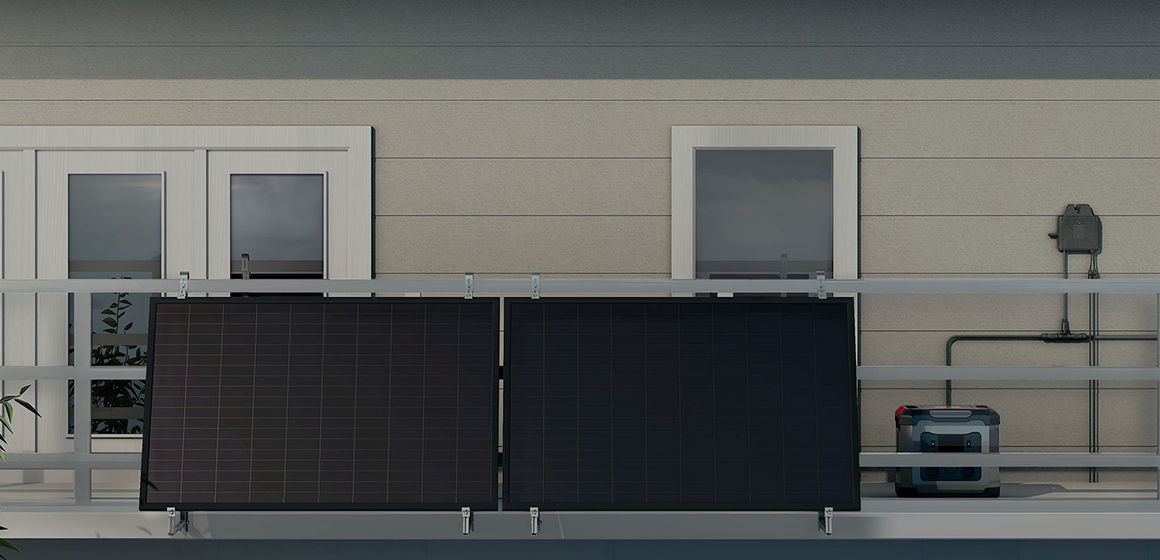

Unveiling the Secrets Behind Solar Power: Discover the Future of Clean Energy!

As the world grapples with climate change and dwindling fossil fuel resources, solar power has emerged as a beacon of hope in the quest for clean energy. The growth of solar power manufacturing has been remarkable, playing a pivotal role in the transition towards sustainable energy sources. With advancements in technology and an increasing focus on environmental responsibility, the solar industry is more relevant than ever. This article will explore the intricate processes, cutting-edge technologies, and rigorous quality assurance measures that underpin high-quality solar power manufacturing, shedding light on how these factors contribute to a greener future.

Understanding Solar Power Manufacturing

Solar power manufacturing refers to the processes involved in producing solar panels and components that convert sunlight into electricity. This sector is a critical component of the renewable energy landscape, offering a sustainable alternative to traditional energy sources. By harnessing the power of the sun, solar power manufacturing helps reduce greenhouse gas emissions, thereby combating climate change. The significance of this industry extends beyond environmental benefits; it also creates jobs, stimulates economic growth, and drives technological innovation. As more countries invest in solar energy, the demand for high-quality solar power manufacturing continues to rise, fueling advancements that make solar technology more efficient and accessible.

Processes Involved in Solar Power Manufacturing

The production of solar panels involves several key steps, each crucial to ensuring the quality and efficiency of the final product. The first step is material selection, where manufacturers choose the raw materials that will be transformed into solar cells. This is followed by cell manufacturing, which converts these materials into functional photovoltaic cells. Finally, module assembly brings together these cells to create complete solar panels. Each of these steps is essential, as they collectively influence the performance, durability, and cost of solar panels, highlighting the importance of precision and quality control throughout the manufacturing process.

Material Selection

Material selection is a fundamental aspect of solar panel manufacturing, primarily focusing on the choice of silicon, the most widely used material for solar cells. Silicon's properties allow for efficient light absorption and conversion into electricity, making it an ideal choice for solar technologies. However, the quality of silicon can vary, impacting the efficiency and longevity of the solar panels. In addition to silicon, other materials such as cadmium telluride and copper indium gallium selenide are gaining traction, offering alternative technologies that may provide cost benefits or improved efficiency. The implications of these material choices are significant, as they directly affect the overall performance and market competitiveness of solar panels.

Cell Manufacturing

Cell manufacturing is the process of converting raw materials, particularly silicon, into solar cells capable of generating electricity. This process typically involves several stages, including crystallization, wafer slicing, and doping. During crystallization, silicon is melted and formed into ingots, which are then sliced into thin wafers. Doping introduces impurities to the silicon, enhancing its electrical conductivity and enabling it to convert sunlight into electricity effectively. Advanced photovoltaic technologies, such as passivated emitter and rear cell (PERC) and bifacial cells, are also being developed to improve energy conversion efficiency. The meticulous nature of cell manufacturing is essential for producing high-quality solar cells that meet performance standards.

Module Assembly

Once solar cells are manufactured, they must be assembled into modules. This step involves arranging the cells in a specific configuration and encapsulating them with protective materials to ensure durability and weather resistance. The quality of module assembly is critical, as it affects the overall performance and lifespan of the solar panels. Proper alignment and soldering of the cells are essential for maximizing energy output and preventing potential failures. The assembly process also includes rigorous testing to ensure that the modules meet international standards for efficiency and safety. This attention to detail during module assembly is what ultimately defines the quality of the final solar product.

Technologies Driving Solar Power Manufacturing

Advanced technologies play a crucial role in enhancing the efficiency and effectiveness of solar power manufacturing. Automation is one of the key innovations, allowing for faster production rates and improved precision in manufacturing processes. Automated systems can handle tasks such as wafer cutting, cell testing, and module assembly with minimal human intervention, reducing the risk of errors and increasing overall output. Furthermore, research into new photovoltaic technologies, such as perovskite solar cells and transparent solar panels, is pushing the boundaries of what is possible in solar manufacturing. These advancements not only promise higher efficiency rates but also aim to lower production costs, making solar energy even more accessible to consumers.

Quality Assurance in Solar Power Manufacturing

Quality assurance is an indispensable aspect of solar power manufacturing, ensuring that solar panels meet the highest standards of reliability and performance. Various testing procedures are employed throughout the manufacturing process, including performance testing, thermal cycling, and mechanical stress tests. These tests help identify potential weaknesses in the solar panels and ensure they can withstand environmental conditions. Additionally, adherence to international standards, such as those set by the International Electrotechnical Commission (IEC), guarantees that products are safe and effective for consumers. The commitment to quality assurance not only enhances the credibility of solar manufacturers but also builds consumer trust in solar technology as a viable energy source.

Key Takeaways on Solar Power Manufacturing

In summary, the journey of solar power manufacturing is intricate and essential for the future of clean energy. From the careful selection of materials to the advanced technologies that enhance production efficiency, each step plays a vital role in ensuring high-quality solar panels. As the world continues to embrace renewable energy, the prospects for solar power manufacturing remain bright, with innovations paving the way for even greater advancements. By investing in high-quality manufacturing processes and maintaining stringent quality assurance measures, the solar industry can significantly contribute to global sustainability efforts and the fight against climate change.