Why Choosing the Right Banana Rollers Supplier Matters for Industrial Applications

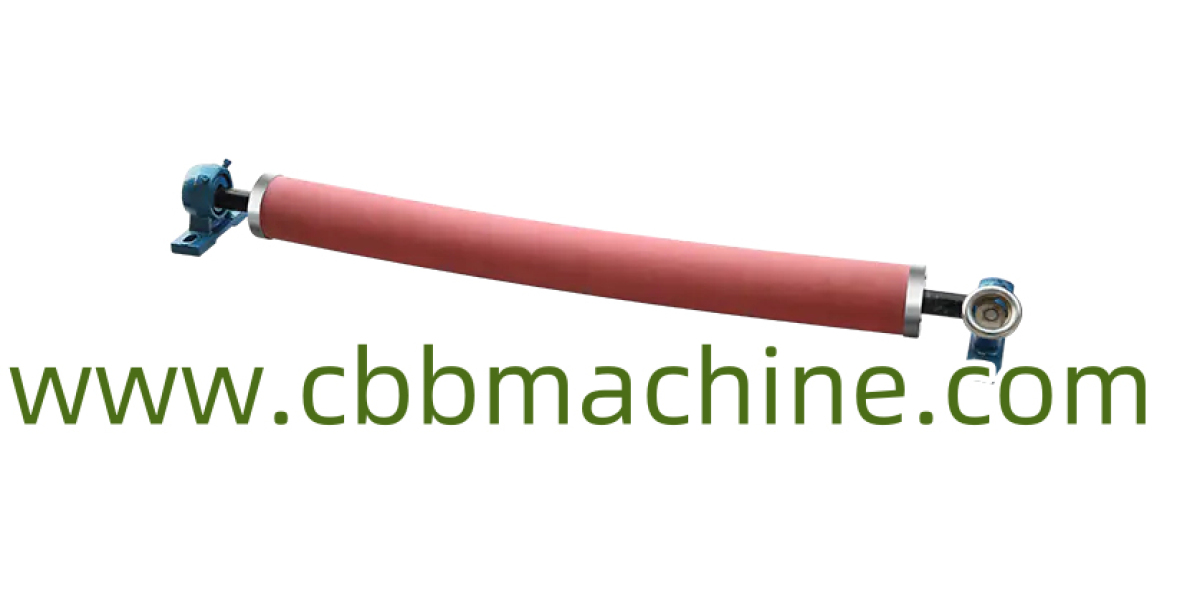

Working with a dependable Banana Roller supplier is crucial for industries that rely on precision web handling and wrinkle elimination during the processing of materials such as plastic films, textiles, paper, and laminates. Banana rollers, also known as bowed rollers, are engineered to correct web misalignment, remove wrinkles, and maintain tension uniformity across wide materials. Their presence in a production line can directly impact quality, efficiency, and machine lifespan.

Banana rollers are widely used in converting, coating, laminating, slitting, printing, and packaging lines. Their unique bowed structure allows them to stretch and align the web, preventing material overlap or fold formation. This process is especially important when working with lightweight or delicate substrates that are prone to deformation under tension.

When selecting a banana roller, several key elements must be considered. These include bow angle, roller diameter, working width, roller surface material, and the intended application. A reliable Banana Rollers supplier can provide the necessary guidance in customizing rollers to match machine configurations and material characteristics. This ensures that the equipment performs efficiently under varying operational conditions.

Material selection is one of the first considerations when choosing a banana roller. The roller’s covering—whether rubber, chrome-plated steel, or other specialized coatings—must match the type of substrate being processed. For instance, rubber-coated rollers are often used to avoid slipping or scratching sensitive films, while chrome-coated rollers offer higher durability in heavy-duty environments.

Another important factor is the roller’s bow angle. The amount of curvature in a banana roller affects how much it spreads the web. A knowledgeable supplier will recommend an angle based on the web width, tension, and speed of the application. Incorrect bow angles may result in insufficient web spreading or excessive material distortion.

Proper installation and alignment are also essential to achieve optimal performance from banana rollers. A trustworthy supplier provides not just the product but also technical support on correct mounting positions and rotation directions. Misalignment or improper tension settings can reduce the effectiveness of the roller or lead to uneven web tension.

Banana rollers also play a significant role in improving overall machine efficiency. By eliminating wrinkles and stabilizing the web path, these rollers reduce the risk of production stoppages due to jams or material misfeeds. This contributes to higher production rates, less waste, and better output quality.

Another reason to collaborate with a professional Banana Rollers supplier is their ability to provide customized solutions. Not every production line requires the same roller design. Depending on the speed of the line, type of material, and temperature conditions, the design of the roller body, the bow mechanism, and the surface treatment can vary significantly.

Some banana rollers are driven mechanically, while others rotate passively with the web. Additionally, features like adjustable bow settings, modular mounting brackets, or anti-static coatings can be incorporated to meet specific industrial needs. Customization of this nature allows a banana roller to be more than just a support tool—it becomes an active component in the quality control system.

Durability and maintenance are other important considerations. High-quality banana rollers are designed to operate continuously over long periods without deformation or performance loss. However, wear and tear over time are inevitable. A good supplier will offer guidance on inspection intervals, maintenance procedures, and replacement schedules to ensure long-term operational reliability.

In a time when precision and consistency are more important than ever, having the right equipment can be the difference between smooth operations and recurring issues. Partnering with a capable Banana Rollers supplier means gaining access to engineering expertise, tailored designs, and dependable support throughout the product lifecycle.

Whether you are setting up a new production line or upgrading an existing one, banana rollers are an essential investment. They contribute to the overall stability of your web handling system, reduce material waste, and help maintain production targets without interruptions. The quality of the roller and the reliability of the supplier both play an essential role in achieving these outcomes.