Unlock the Secret to Choosing the Perfect 3D Printer Filament!

Choosing the right filament for your 3D printer is crucial for achieving high-quality prints that meet your project requirements. The filament you select can significantly affect not only the appearance of your printed object but also its durability and functionality. From creating intricate designs for hobby projects to producing robust components for engineering applications, the type of filament can make all the difference. This article aims to guide you through the maze of filament options available in the market, helping you evaluate and select the best filament for 3D printer suited to your needs.

Understanding 3D Printer Filament Types

When it comes to 3D printing, several types of filaments are commonly used, each with unique characteristics and applications. One of the most popular types is PLA (Polylactic Acid), known for its ease of use and biodegradability. It's an excellent choice for beginners and produces prints with vibrant colors and a smooth finish. On the other hand, ABS (Acrylonitrile Butadiene Styrene) is favored for its strength and durability, making it suitable for functional parts. However, it requires a heated bed and proper ventilation due to fumes emitted during printing.

PETG (Polyethylene Terephthalate Glycol) has gained popularity due to its balance between strength and flexibility, along with good chemical resistance. This makes it an ideal choice for items that need to endure stress. Other filaments, like TPU (Thermoplastic Polyurethane), are flexible, allowing for the creation of rubber-like objects, while nylon offers exceptional strength and resilience, often used in industrial applications. Understanding these filament types will help you make informed decisions based on the requirements of your project.

Factors to Consider When Choosing Filament

Several key factors influence your choice of filament, each impacting the quality and functionality of your final print. First, consider the printing temperature; different filaments require specific temperatures for optimal results. For instance, PLA prints well at lower temperatures, while ABS and PETG need higher temperatures to avoid warping.

Next, think about the strength and flexibility required for your project. If you’re creating parts that need to withstand mechanical stress, you might lean towards more robust materials like ABS or nylon. Conversely, if you need something more pliable, TPU may be the way to go. Environmental considerations are also vital; if your printed object will be exposed to heat or moisture, selecting a filament with suitable properties is essential to ensure longevity.

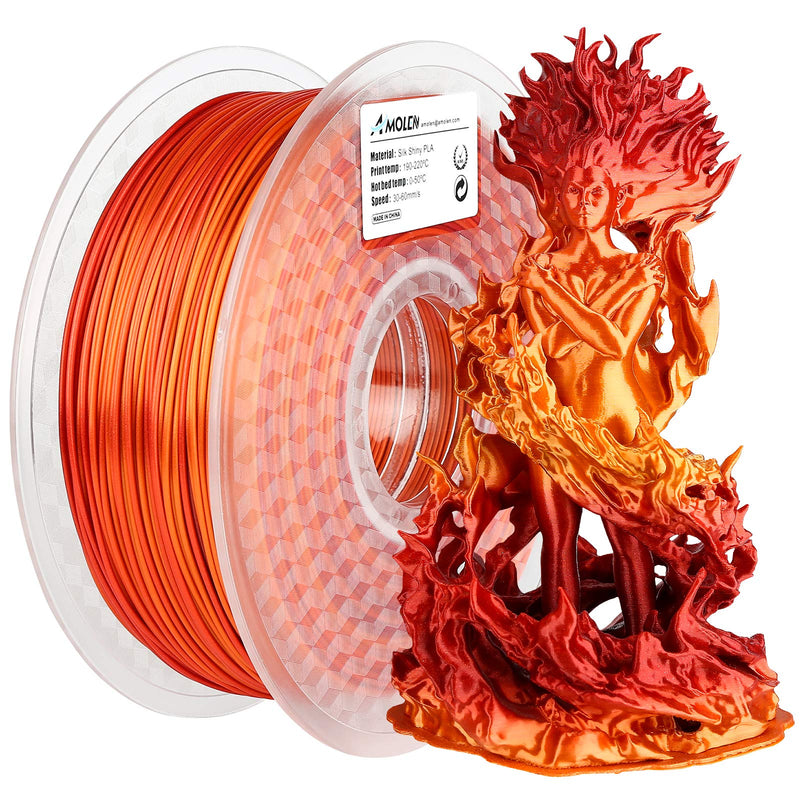

Additionally, consider the aesthetic aspects, such as color and finish. Some filaments offer a glossy finish, while others have a matte appearance, which can influence the overall look of your project. Understanding these factors allows you to align your filament choice with your specific needs, enhancing the success of your prints.

Evaluating Filament Quality

The quality of filament is paramount, as it directly impacts print success. When assessing filament quality, start by examining the diameter consistency. A uniform diameter is crucial for reliable feeding through the printer's extruder. Inconsistencies can lead to under-extrusion or over-extrusion during printing, resulting in poor-quality prints.

Another aspect to consider is color fidelity; high-quality filaments maintain their color accurately throughout the spool. This is especially important if your project requires specific shades or if you plan on painting your prints. Lastly, the material purity plays a vital role in achieving optimal print results. Sourcing filament from reputable suppliers, who ensure stringent quality control measures, will help you avoid issues like clogs and inconsistent extrusion, which can mar your printing experience.

Best Practices for Using 3D Printer Filament

Proper storage of filament is essential. Filament should be stored in airtight containers or vacuum-sealed bags to maintain moisture absorption and adhesion. If not, moisture can lead to bubbling issues during printing, resulting in poor quality.

When preparing to print, ensure your printer is calibrated correctly. This includes checking the nozzle temperature and bed adhesion to prevent warping or lifting. During the printing process, pay attention to the first layer; it’s crucial for the overall success of your print. A common pitfall is neglecting to clean the print bed, which can lead to poor adhesion and failed prints. Following these best practices will help you achieve successful prints and prolong the lifespan of your filament.

Final Thoughts on Choosing Filament

In conclusion, selecting the right filament for your 3D printing projects is a decision that should not be taken lightly. Understanding the various types of filaments, considering critical factors such as temperature, strength, and quality, and following best practices for use can significantly enhance your printing experience. By taking the time to evaluate your specific needs and preferences, you can unlock the potential of your 3D printer and achieve impressive results. Happy printing!