Unlock the Secrets of TPU Filament: Discover Its Amazing Properties and Game-Changing Uses in 3D Printing!

In the rapidly evolving world of 3D printing, materials play a pivotal role in determining the quality and functionality of printed objects. One such material that has gained significant traction is TPU filament, a type of thermoplastic elastomer that offers a unique blend of flexibility and durability. Understanding TPU filament is essential for enthusiasts and professionals alike, as it opens up a world of possibilities for innovative designs and applications. In this article, we will delve into the properties that make TPU filament stand out, explore its myriad benefits for 3D printing, and uncover its diverse applications across various industries. By the end of this read, you'll have a comprehensive understanding of TPU filament and how it can elevate your 3D printing projects.

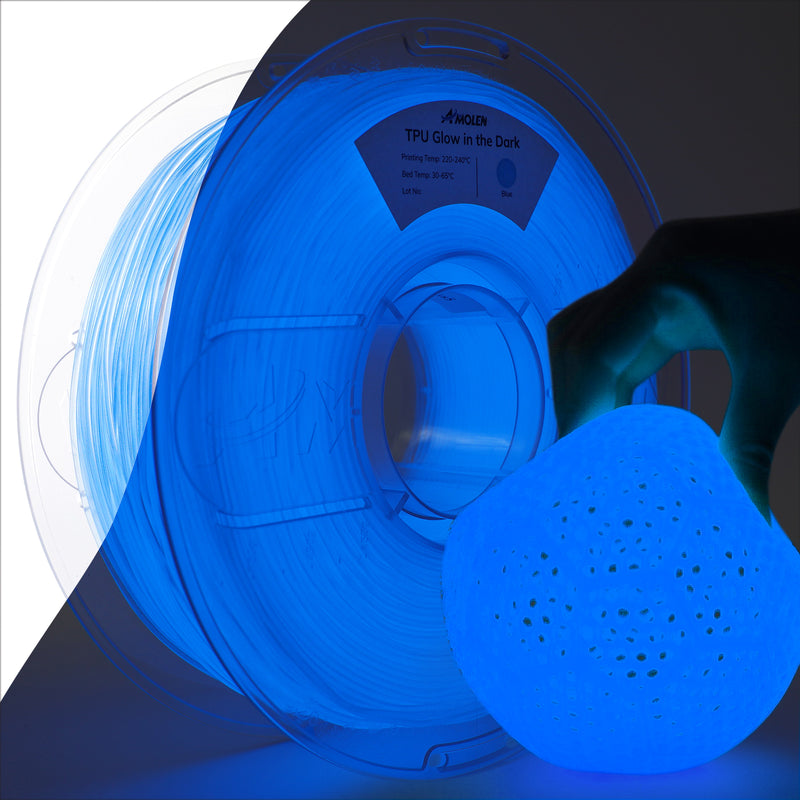

Understanding TPU Filament

TPU, or Thermoplastic Polyurethane, is a versatile filament made from a combination of soft and hard segments, allowing it to exhibit both rubber-like and plastic-like properties. This unique chemical composition places TPU within the category of thermoplastic elastomers, which are known for their elasticity and resilience. Unlike traditional plastics, TPU can be stretched, compressed, and returned to its original shape without permanent deformation. This characteristic makes it an ideal choice for applications that require flexibility and durability. My friend, an avid 3D printing hobbyist, often raves about how TPU filament has transformed his projects, enabling him to create everything from phone cases to intricate wearable designs that maintain their shape and functionality over time.

Properties of TPU Filament

TPU filament boasts several key properties that contribute to its popularity among 3D printing enthusiasts. One of its most notable features is its exceptional flexibility, allowing printed objects to bend and stretch without breaking. This flexibility is complemented by impressive strength and durability, making TPU resistant to wear and tear. Additionally, TPU exhibits excellent abrasion resistance, making it suitable for applications that require frequent handling or movement. Moreover, this filament is resistant to a variety of chemicals, including oils and greases, which further broadens its usability in different environments. These attributes have inspired many of my friends to experiment with TPU, resulting in unique and functional designs that stand the test of time.

Benefits of Using TPU Filament in 3D Printing

Using TPU filament in 3D printing comes with a plethora of benefits that make it a preferred choice for many makers. One of the most significant advantages is its ease of use; TPU filaments are generally compatible with a wide range of 3D printers, including those that support flexible materials. This versatility enables creators to tackle complex geometries and intricate designs that traditional rigid filaments might struggle with. Additionally, TPU’s ability to produce soft-touch surfaces and detailed textures enhances the aesthetic appeal of printed objects. Another benefit is the filament's ability to absorb impact, making it an excellent choice for items that require shock resistance. I remember a project where a friend used TPU to create custom grips for gaming controllers—something that not only improved comfort but also added a personal touch to his gaming experience.

Applications of TPU Filament

The applications of TPU filament are vast and varied, spanning multiple industries. In the automotive sector, TPU is often used to produce flexible components such as seals, gaskets, and protective covers that require durability and flexibility. In the medical field, TPU is gaining traction for creating prosthetics and orthopedic devices that require a balance of comfort and resilience. The fashion industry is also tapping into TPU's potential, with designers creating unique accessories and wearable items that challenge traditional concepts of fashion. Additionally, consumer products like phone cases, sporting goods, and toys benefit from TPU's properties. The ability to create functional and aesthetically pleasing items has sparked creativity among makers, leading to innovative designs that were previously unimaginable.

Elevating 3D Printing with TPU Filament

In conclusion, TPU filament represents a significant advancement in the realm of 3D printing, offering an impressive combination of flexibility, strength, and versatility. From its chemical composition to its wide array of applications, TPU stands out as a material that can enhance both the functionality and creativity of printed objects. As technology continues to evolve, embracing materials like TPU can lead to groundbreaking innovations in design and manufacturing. Whether you're a seasoned professional or a newcomer to 3D printing, exploring the possibilities with TPU filament could be the key to unlocking your next project. Don't hesitate to incorporate TPU into your workflow; its unique properties may just inspire you to create something extraordinary!