The system integrator industrial automation Market Growth is driven by the increasing adoption of automated manufacturing processes, the rise of IoT-enabled equipment, and demand for higher productivity and reduced operational costs. Industries are realizing the importance of integrating automation systems to stay competitive. Growth is further supported by government initiatives encouraging modernization of factories and adoption of Industry 4.0 practices. The continuous development of AI-based solutions and predictive maintenance systems also fuels market expansion.

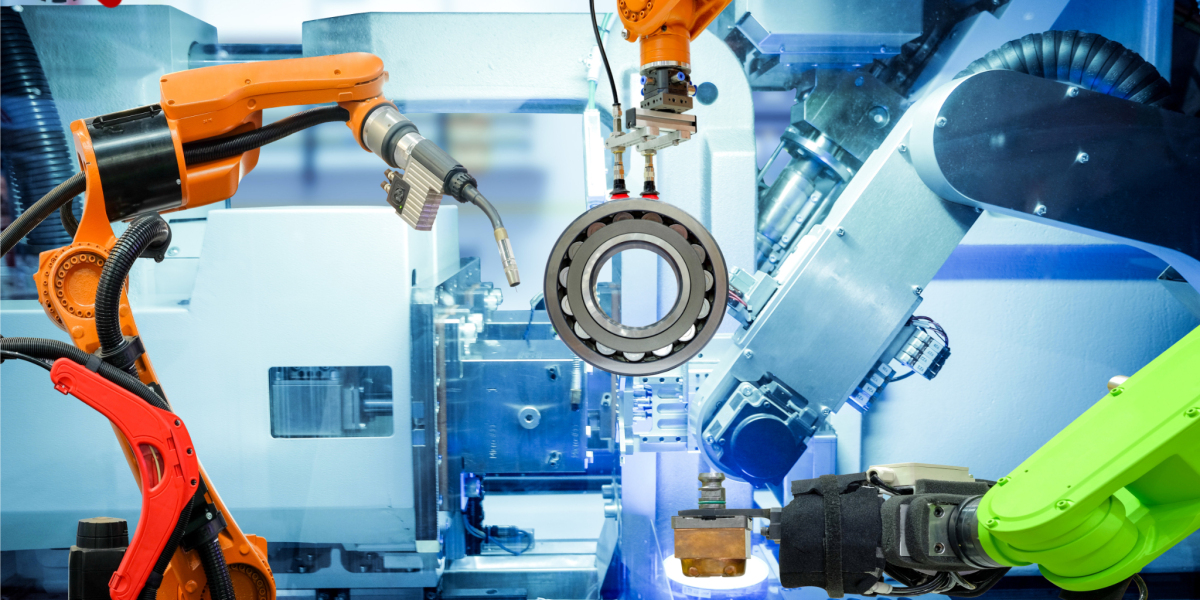

The system integrator industrial automation market is witnessing rapid growth as industries across the globe strive for operational efficiency, cost reduction, and technological advancement. System integrators play a pivotal role in connecting complex industrial systems, ensuring seamless communication between machines, processes, and software platforms. Their expertise allows manufacturers to optimize production workflows, reduce downtime, and enhance overall productivity.

Market Overview

The industrial automation sector has evolved significantly over the past decade, fueled by advancements in robotics, Internet of Things (IoT), artificial intelligence (AI), and smart factory technologies. System integrators act as the bridge between these innovations and industrial operations. They provide tailored solutions that integrate hardware, software, and network components, allowing manufacturers to achieve higher levels of automation. The market is expanding rapidly due to increasing adoption of automated systems in sectors like automotive, pharmaceuticals, chemicals, electronics, and food and beverages.

System integrators offer end-to-end services, from designing automation strategies to implementing and maintaining them. Their solutions often include programmable logic controllers (PLCs), human-machine interfaces (HMIs), SCADA systems, and robotics integration. By combining various technological components, system integrators help industries reduce manual intervention, improve accuracy, and enhance production efficiency.

Market Dynamics

The market dynamics in system integrator industrial automation are shaped by several factors. On one hand, the demand for operational efficiency and cost reduction drives industries to adopt automation solutions. On the other, the rapid pace of technological advancement requires integrators to stay updated with emerging tools, software, and communication protocols.

In addition, global trends such as Industry 4.0, smart manufacturing, and predictive maintenance are creating new opportunities for system integrators. Companies are increasingly focusing on digital transformation, and integrators provide the expertise to implement these strategies. With the growing complexity of industrial operations, the role of system integrators becomes crucial in ensuring that automation systems work efficiently and are scalable for future needs.

Key Drivers

Several key drivers are propelling the growth of the system integrator industrial automation market:

Rising Need for Efficiency: Industries are under pressure to enhance productivity while reducing operational costs. Automated systems designed by integrators help achieve these objectives.

Technological Advancements: Innovations in AI, machine learning, IoT, and robotics provide new opportunities for system integrators to design intelligent, connected solutions.

Global Industrial Expansion: Emerging markets are witnessing rapid industrialization, leading to increased adoption of automation solutions.

Regulatory Compliance: Industries are increasingly required to meet safety and environmental standards. Automation helps ensure compliance while maintaining production efficiency.

Market Restraints

Despite the positive growth outlook, the market faces several challenges and restraints:

High Initial Investment: Automation solutions often require significant capital investment, which may be a barrier for small and medium-sized enterprises.

Complex Integration Processes: Integrating multiple systems from different manufacturers can be challenging and may require skilled labor and expertise.

Cybersecurity Concerns: Increased connectivity in automated systems makes them vulnerable to cyberattacks, requiring system integrators to implement robust security measures.

Skilled Workforce Shortage: The need for professionals with expertise in automation, robotics, and software integration remains high, and the shortage can limit market expansion.

Segmentation of the Market

The system integrator industrial automation market can be segmented based on type, application, and region.

By Type: System integrators may offer hardware integration, software solutions, networking services, or complete end-to-end solutions. Each segment serves unique industry requirements, with end-to-end integration seeing the highest adoption.

By Application: Key applications include automotive manufacturing, chemical processing, electronics assembly, food and beverage processing, pharmaceuticals, and energy management. Automotive and electronics sectors are major contributors due to high production volumes and complexity.

By Region: North America and Europe remain leading markets due to advanced industrial infrastructure and technology adoption. However, Asia-Pacific is emerging as a high-growth region driven by industrial expansion, government initiatives, and increasing automation awareness.

Challenges and Market Constraints

While the growth potential is significant, system integrators face operational and strategic challenges. Integrating legacy systems with modern automation technologies can be difficult, requiring customized solutions. Additionally, fluctuating economic conditions, trade policies, and supply chain disruptions can affect market stability. The need for continuous technological upgradation also demands high investment in research and training, which may not be feasible for all integrators.

Future Outlook

The future of the system integrator industrial automation market is promising, driven by digital transformation, smart manufacturing, and Industry 4.0 initiatives. Companies are expected to invest in advanced analytics, AI-driven process optimization, and predictive maintenance solutions. Cloud-based automation systems and remote monitoring tools are also gaining traction, providing opportunities for system integrators to offer innovative services.

CNC Polishing Machines Market Share

Americas Packaged Water Treatment System Market Share

India Seed and Grain Cleaning and Grading Machine Market Share