Unlocking the Secrets of 3D Printing: Discover the Perfect Filament for Your Next Project!

The world of 3D printing is a fascinating realm that combines creativity, technology, and engineering. One of the most critical aspects of achieving high-quality prints lies in selecting the right filament. The filament you choose can significantly impact the durability, appearance, and functionality of your final product. With a wide array of filaments available, ranging from biodegradable options to high-strength materials, understanding their unique properties is essential for any successful 3D printing project. Whether you're a hobbyist looking to create decorative items or a professional needing functional prototypes, the best filament for 3d printer is the key to unlocking your project’s potential.

Understanding 3D Printing Filaments

Filament is the material used in 3D printing, fed into the printer to create objects layer by layer. Different filaments possess distinct physical properties, such as melting temperature, strength, flexibility, and adhesion characteristics, which directly affect print quality and suitability for various applications. For instance, some filaments may be easier to print with but less durable, while others may require specific temperature settings or environments to achieve the best results. Understanding these properties is crucial for selecting the right filament that meets your project’s requirements and ensures a successful printing experience.

Types of 3D Printing Filaments

There are several types of 3D printing filaments available, each with its unique characteristics, advantages, and ideal use cases. Here’s a closer look at some of the most popular filaments:

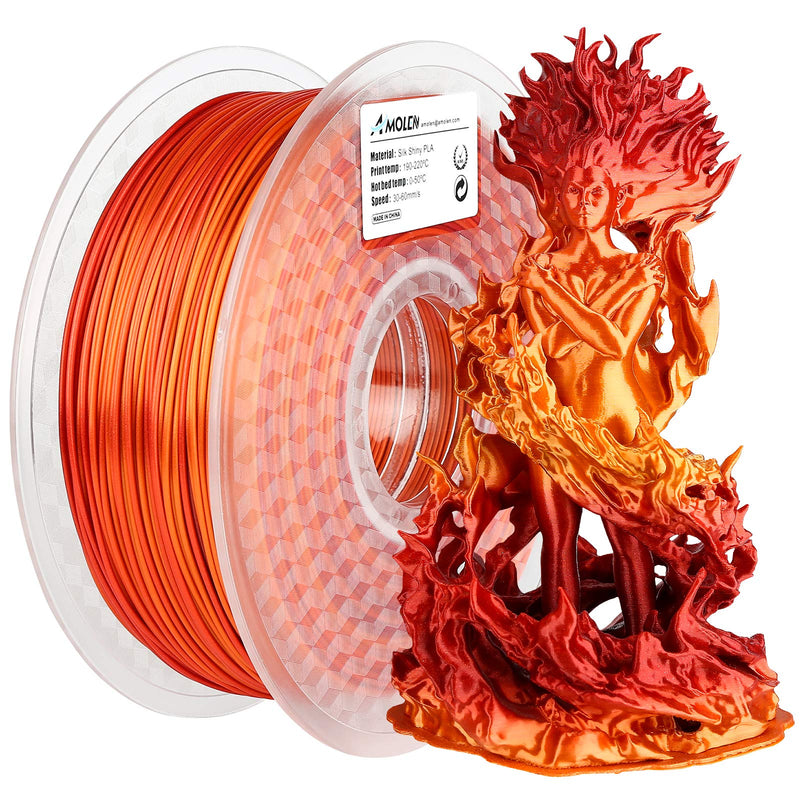

PLA Filament

PLA (Polylactic Acid) filament is one of the most commonly used materials in 3D printing. Made from renewable resources like cornstarch, PLA is biodegradable and easy to print, making it a favorite among beginners. It adheres well to the print bed and comes in a variety of colors and finishes. However, while PLA is great for creating detailed models and prototypes, it is less heat-resistant than other materials, making it unsuitable for applications that involve high temperatures, such as automotive parts.

ABS Filament

ABS (Acrylonitrile Butadiene Styrene) filament is known for its durability and strength, making it an excellent choice for functional parts and prototypes. It can withstand higher temperatures than PLA and is more resistant to impact. However, printing with ABS can be challenging due to its tendency to warp if not printed in a controlled environment, so a heated bed is often recommended. Many of my friends who work with ABS appreciate its versatility for creating items like phone cases and mechanical components.

PETG Filament

PETG (Polyethylene Terephthalate Glycol) filament is a strong, flexible option that combines the advantages of both PLA and ABS. It has excellent layer adhesion, making it suitable for functional parts that require durability and impact resistance. PETG is also resistant to moisture, which adds to its versatility. I often hear from fellow makers that PETG is their go-to choice for projects that need a balance between strength and flexibility, such as custom containers or outdoor items.

TPU Filament

TPU (Thermoplastic Polyurethane) filament is known for its flexibility and rubber-like properties. It is perfect for creating objects that require elasticity, such as phone cases, gaskets, and wearables. However, printing with TPU can be tricky due to its flexibility, which can lead to feeding issues in some printers. Nevertheless, for those willing to experiment, TPU can result in impressive, functional designs that traditional rigid filaments cannot achieve.

Nylon Filament

Nylon filament is celebrated for its toughness and versatility, making it a popular choice in engineering applications. Its strength and resistance to wear make it suitable for producing functional parts such as gears, hinges, and other mechanical components. However, nylon can absorb moisture from the air, which may affect print quality, so it requires careful storage and handling. Friends who work in mechanical engineering often choose nylon for prototypes that need to withstand stress and strain.

Choosing the Right Filament for Your Project

When selecting the right filament for your 3D printing project, consider several factors, including the intended use, required strength, flexibility, and environmental considerations. For decorative models, PLA may be the best option due to its ease of use and aesthetic appeal. For functional parts, you might opt for ABS or PETG for their durability. Additionally, if your project requires flexibility, TPU is a great choice. Always consider the specific requirements of your project and the capabilities of your 3D printer to ensure you select the best filament for the job. Remember, the right filament can make all the difference in achieving your desired results.

Key Takeaways on Filament Selection

Selecting the best filament for your 3D printing projects is essential for achieving quality results that meet your needs. Understanding the different types of filaments and their unique properties allows you to make informed decisions based on your project requirements. From the easy-to-use PLA to the durable ABS, flexible TPU, and versatile nylon, each filament has its place in the world of 3D printing. By carefully considering your project’s goals and the capabilities of various materials, you can unlock the full potential of your 3D printer and create amazing objects that stand the test of time.