Unlock the Magic of Multi-Color 3D Printing: Discover the Future of Creativity!

Multi-color 3D printing represents a fascinating intersection of technology and creativity, allowing artists, designers, and engineers to push the boundaries of what is possible in three-dimensional creation. This innovative technology has evolved significantly since the early days of 3D printing, when models were typically limited to a single color and relatively simplistic designs. With advancements in printing techniques and materials, multi color 3D printers now enable the production of stunningly detailed and vibrant objects that can capture the imagination. In this article, we will delve into the features, benefits, and various types of multi-color 3D printers, showcasing how they are transforming the creative landscape.

Understanding Multi-Color 3D Printing

Multi-color 3D printing refers to the capability of printers to produce objects with multiple colors within a single print job. Unlike traditional 3D printing methods, which typically utilize a single filament or resin, multi-color printing incorporates various materials that can be blended or layered to achieve a rich palette of colors. This allows for the creation of intricate designs that would be challenging, if not impossible, to achieve with single-color printing. The technology behind multi-color printing varies, but common methods include Fused Deposition Modeling (FDM) and Stereolithography (SLA), each employing different techniques to build up layers of material. FDM printers, for instance, use thermoplastic filaments that are heated and extruded, while SLA printers utilize liquid resins cured by UV light. Both methods can utilize multiple materials to create vibrant, multi-colored objects.

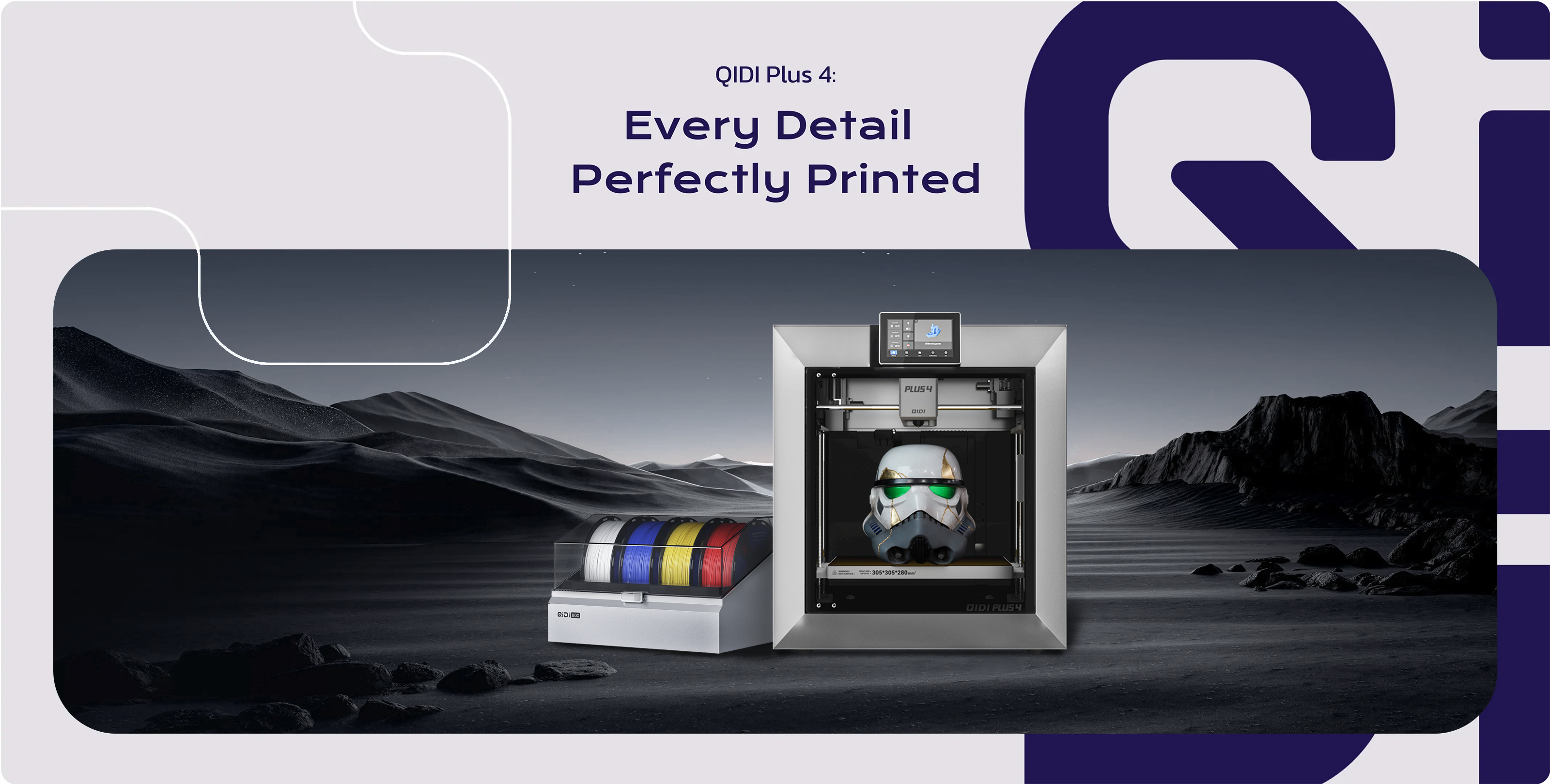

Features of Multi-Color 3D Printers

Multi-color 3D printers come equipped with several key features that enhance their functionality and usability. One of the most significant features is high print resolution, allowing for the production of detailed and intricate designs. Many modern printers can achieve layer heights as fine as 20 microns, resulting in smooth finishes and precise details. Speed is another important aspect, with advancements in technology enabling faster print times without compromising quality. Additionally, versatility is a hallmark of multi-color printers, as they can handle various materials, including flexible filaments and composite materials, making them suitable for a wide range of applications. Some printers even include advanced features such as automatic bed leveling, multi-material capabilities, and connectivity options that allow for remote printing and monitoring, further enhancing the overall printing experience.

Benefits of Multi-Color 3D Printing

The benefits of utilizing multi-color 3D printers are significant, particularly in fostering enhanced creativity and innovation. Artists and designers can create detailed, visually striking models that tell a story or convey complex ideas through color. This capability is invaluable for prototyping, as it allows for the development of realistic representations of products that can better communicate concepts to clients and stakeholders. Moreover, multi-color printing can streamline the production process by reducing the need for post-processing steps, such as painting or assembly, thereby saving time and resources. Industries such as architecture, fashion, and automotive design are increasingly adopting multi-color 3D printing for its ability to produce rapid prototypes, customized products, and intricate designs that meet specific consumer demands.

Types of Multi-Color 3D Printers

There are several types of multi-color 3D printers, each with its unique operation and applications. Fused Deposition Modeling (FDM) printers are among the most common, utilizing multiple extruders to dispense different colored filaments simultaneously. This allows for a seamless blend of colors and intricate designs. Stereolithography (SLA) printers, on the other hand, employ a different method, using a laser to cure resin into solid layers. Some SLA printers now offer multi-material capabilities, allowing for the combination of different resin types and colors. Additionally, there are PolyJet printers, which can jet tiny droplets of photopolymer materials that solidify upon exposure to UV light, enabling the creation of highly detailed and colorful objects. Each type of printer has its strengths and is better suited for specific projects, whether it be for rapid prototyping or artistic endeavors.

Embracing the Future of Multi-Color 3D Printing

In summary, multi-color 3D printing is a revolutionary technology that has opened new avenues for creativity and innovation across various industries. By understanding its features, benefits, and the different types of printers available, individuals and businesses can harness the potential of this technology to create stunning, detailed models and prototypes. As 3D printing continues to evolve, the possibilities for multi-color printing will only expand, encouraging more creators to explore its transformative potential. Whether you're an artist looking to bring your visions to life or a company seeking efficient prototyping solutions, multi-color 3D printing offers exciting opportunities to elevate your projects and realize your creative dreams.