Unlock the Magic of TPU: The Ultimate Game-Changer in 3D Printing!

In the ever-evolving world of 3D printing, Thermoplastic Polyurethane (TPU) filament is emerging as a transformative material that is capturing the attention of hobbyists and professionals alike. TPU is a flexible filament that offers a unique blend of properties that set it apart from traditional rigid filaments. Its growing popularity can be attributed to its adaptability across various applications, from creating intricate prototypes to producing functional end-use parts. This article delves into the significance of TPU in 3D printing, exploring its unique characteristics that make it a standout choice for diverse projects.

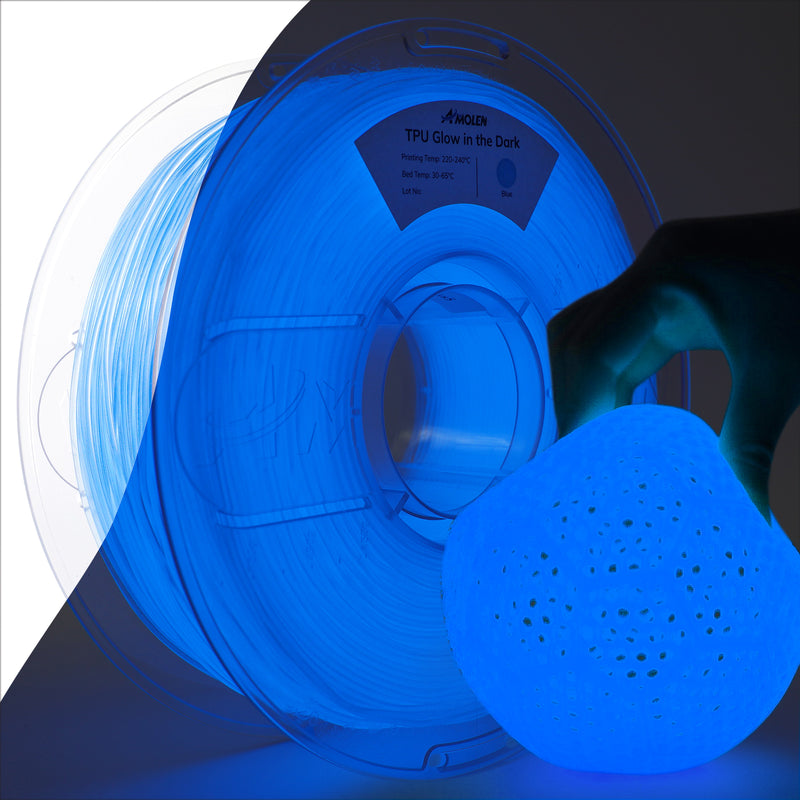

Understanding TPU Filament

TPU, or Thermoplastic Polyurethane, is a type of polymer that falls under the category of elastomers. Its chemical structure consists of linear macromolecules made from soft and hard segments, allowing it to exhibit both flexibility and strength. This unique composition gives TPU its distinguishing properties, differentiating it from other filament types. Unlike PLA or ABS, TPU is remarkably flexible, which allows it to bend and stretch without breaking. Furthermore, its durability makes it resistant to wear and tear, making it an excellent choice for applications that require longevity. Friends of mine who have experimented with TPU filament have found it particularly satisfying to print with, as it results in highly detailed and functional parts that can withstand daily use.

Properties of TPU Filament

TPU filament boasts a variety of key properties that enhance its performance in 3D printing. One of its most notable features is its tensile strength, which allows it to endure significant stress without deforming. Flexibility is another crucial property; TPU can stretch up to several times its original length, making it ideal for applications that require movement or compression. Additionally, TPU exhibits excellent temperature resistance, maintaining its integrity under varying thermal conditions. Its chemical resistance is equally impressive, allowing it to withstand exposure to oils, greases, and various solvents. These properties not only influence how the filament performs during printing but also determine the quality and resilience of the finished products. In my experience, prints made from TPU have a smooth finish and hold up well under daily wear, an advantage for anyone looking to create durable items.

Applications of TPU in 3D Printing

The versatility of TPU opens the door to a myriad of applications in 3D printing. One prominent use is in prototyping; designers can create flexible models that accurately represent the final product's functionality. Moreover, TPU is increasingly popular in the consumer products sector, where items such as phone cases, footwear, and wearables benefit from its flexibility and durability. The medical field also sees innovative uses for TPU, including the production of prosthetics and custom medical devices that require comfort and adaptability. Furthermore, the automotive industry frequently employs TPU for components that require both resilience and flexibility, such as grommets and seals. A friend of mine recently printed a custom car part using TPU and was thrilled with how well it fit and functioned, demonstrating the filament's ability to meet industry-specific needs.

Tips for Printing with TPU

When it comes to successfully printing with TPU filament, there are several tips that can enhance the experience. First, adjusting the settings of your 3D printer is crucial; lower printing speeds can help prevent issues such as clogging and stringing. Additionally, ensuring proper bed adhesion is vital; using a heated bed and applying adhesives like glue stick or painter's tape can help the filament stick during printing. Post-processing techniques, such as carefully trimming excess material or smoothing the surface, can further improve the final product's appearance. Common challenges when printing with TPU include warping and stringing, but these can be mitigated through careful calibration and practice. My own experience with TPU taught me the value of patience and experimentation, as it took a few tries to perfect my settings for the best results.

Embracing the Potential of TPU Filament

In conclusion, TPU filament presents a wealth of advantages for 3D printing enthusiasts and professionals alike. Its unique properties, including flexibility, durability, and resistance to various elements, make it an invaluable material for a wide range of applications. From prototyping to end-use products in industries such as automotive and medical, TPU is proving to be a game-changer in product design and innovation. I encourage readers to explore the possibilities that TPU offers for their own projects, as its potential to enhance functionality and creativity is truly remarkable. Whether you’re a seasoned pro or just starting, TPU could be the next exciting step in your 3D printing journey.