Unlock the Secrets of PETG Filament: Why Every 3D Printer Enthusiast Needs It!

In the vibrant world of 3D printing, one material has been steadily gaining traction among both hobbyists and professionals: PETG filament. Known for its versatility and impressive performance, PETG has become a favorite choice for those looking to create durable and high-quality prints. Its unique blend of properties makes it suitable for a wide range of applications, from intricate prototypes to robust functional parts. This article will delve into the properties, uses, and benefits of PETG filament, shedding light on why it should be a staple in every 3D printer enthusiast's toolkit.

Understanding PETG Filament Properties

PETG, which stands for Polyethylene Terephthalate Glycol, is a thermoplastic polyester that combines the best attributes of both PET and glycol. This unique chemical composition results in a filament that is not only strong and durable but also flexible and resistant to impact. Compared to other common filament types like PLA and ABS, PETG stands out due to its enhanced toughness and temperature resistance. While PLA is biodegradable and easy to print, it lacks the durability needed for functional parts. On the other hand, ABS, while strong, can warp during printing and emit unpleasant fumes. PETG strikes a balance, offering a low tendency to warp, making it easier to print without the need for a heated bed. Furthermore, PETG exhibits excellent layer adhesion, which enhances the overall strength of printed objects and reduces the risk of print failure. In my experience, a friend of mine had tried various filaments for his 3D printing projects, and after switching to PETG, he noticed a significant improvement in the quality and durability of his prints.

Common Uses of PETG Filament

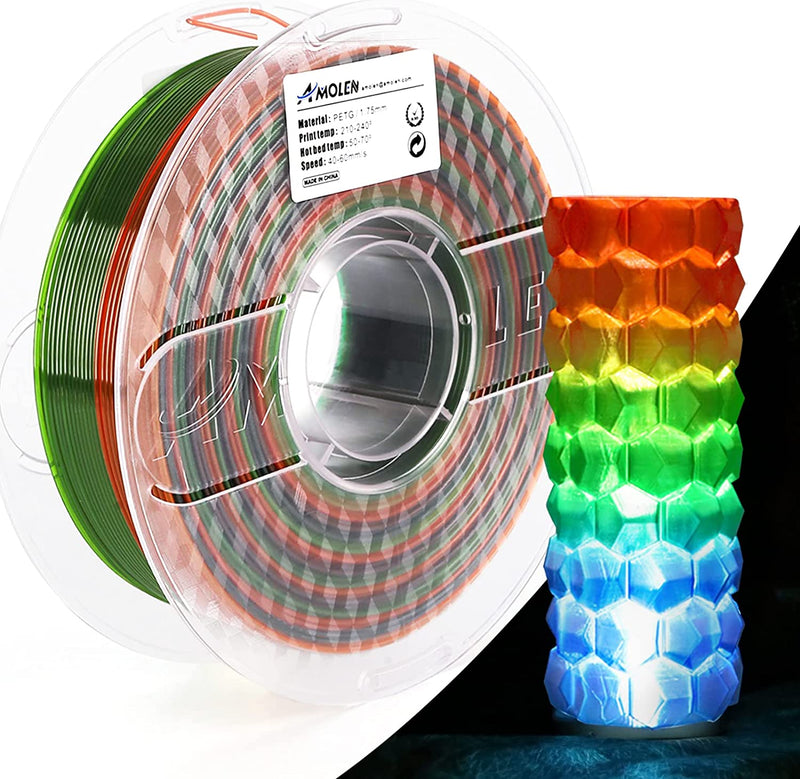

The versatility of PETG filament opens up a myriad of possibilities in the 3D printing industry. One of the most common applications is in prototyping, where rapid development and testing of designs are essential. Its strength and flexibility make it an ideal choice for creating functional prototypes that can withstand real-world testing. Additionally, PETG is an excellent option for producing functional parts, such as mechanical components, brackets, and housings, due to its durability and resistance to chemical exposure. For instance, in the automotive industry, PETG is increasingly used for creating custom parts that require both precision and resilience. Lastly, PETG's aesthetic appeal makes it a popular choice for artistic projects. Artists and designers appreciate its glossy finish and the ability to print intricate designs with clarity. A local artist I know created stunning sculptures using PETG, impressing viewers with the fine details and vibrant colors achievable with this filament. The adaptability of PETG in various fields truly showcases its importance in the realm of 3D printing.

Benefits of Using PETG Filament for 3D Printing

When considering materials for 3D printing, the benefits of PETG filament are hard to overlook. One of the standout advantages is its ease of printing. PETG is known for its forgiving nature, allowing users to achieve excellent results without extensive tweaking of print settings. Unlike some other materials, it has a low tendency to warp, significantly reducing the chances of print failures and wasted filament. Moreover, the improved layer adhesion of PETG enhances the structural integrity of printed objects, making them suitable for practical applications. Another compelling reason to choose PETG is its environmental impact. Compared to other filaments, PETG is less toxic and is recyclable, making it a more sustainable option for eco-conscious creators. This aspect resonates with many users, as they seek to minimize their environmental footprint while enjoying their 3D printing hobby. Reflecting on conversations with fellow enthusiasts, many have praised PETG for its reliable performance and eco-friendliness, which often leads them to prioritize it over other materials for their projects.

Key Takeaways on PETG Filament

In summary, PETG filament emerges as a versatile and valuable material for 3D printing, combining durability, flexibility, and ease of use. Its unique properties make it suitable for a wide range of applications, from prototyping and functional parts to artistic endeavors. The benefits of using PETG, including reduced warping, improved layer adhesion, and a lower environmental impact, make it an ideal choice for both beginners and experienced enthusiasts. As you explore the exciting possibilities of 3D printing, consider incorporating PETG filament into your projects. Its potential to enhance the quality and durability of your prints is undeniable, and it may just become your go-to filament for future creations.