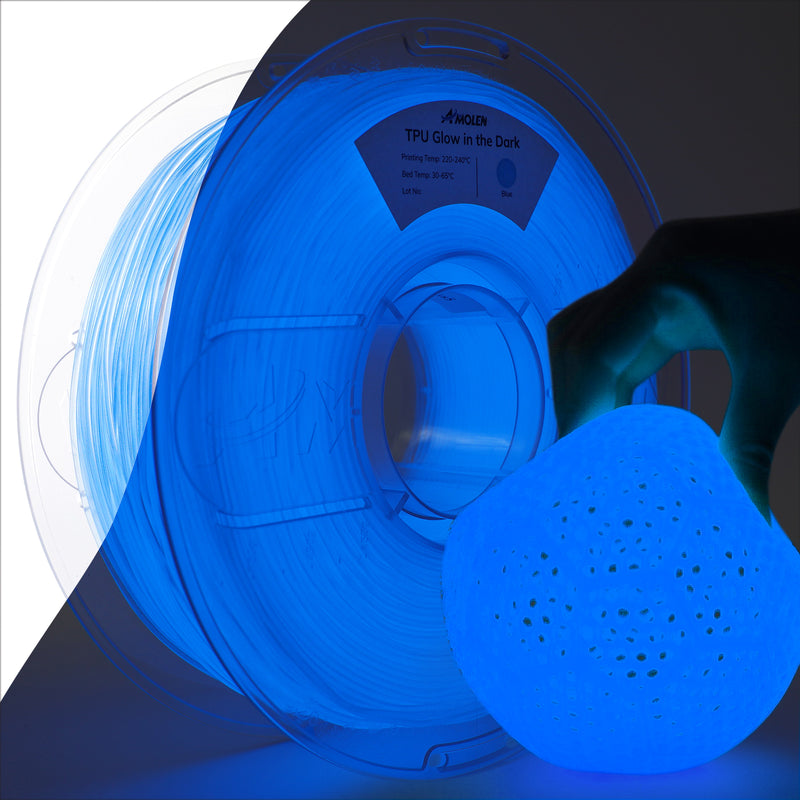

Unlocking the Magic of TPU 3D Printer Filament: Discover Its Features, Uses, and Amazing Benefits!

In the rapidly evolving world of 3D printing, TPU (Thermoplastic Polyurethane) 3D printer filament has gained significant traction for its unique properties and versatility. While traditional filaments like PLA and ABS dominate the market, TPU offers a different set of characteristics that make it increasingly popular among makers and professionals alike. What sets TPU apart is its incredible flexibility and durability, which allow for the creation of both functional and aesthetic parts that require a bit of give. As someone who has witnessed friends use TPU for their projects, I can attest to its potential to transform designs that would otherwise be limited by more rigid materials.

Understanding TPU: What is TPU 3D Printer Filament?

TPU, or Thermoplastic Polyurethane, is a type of elastomer that combines the properties of rubber and plastic. This unique filament is known for its excellent flexibility and resilience, making it ideal for applications that require stretching and bending. Unlike standard filaments, TPU can endure significant deformation without losing its original shape, which is a crucial factor in many practical applications. Its durability is further complemented by good resistance to wear and tear, chemicals, and oil, making it a popular choice in environments where other filaments would degrade. The distinct characteristics of TPU provide a stark contrast to more brittle materials, allowing for the creation of parts that are both robust and lightweight.

Features of TPU 3D Printer Filament

One of the standout features of TPU filament is its elasticity. This allows for the production of flexible parts, such as phone cases or custom gaskets, that can absorb shocks and vibrations effectively. Additionally, TPU exhibits excellent temperature resistance, maintaining its flexibility across a range of conditions. Its ease of printing is another significant advantage; with the right settings, it can be successfully printed on most standard 3D printers equipped with a direct drive extruder. The ability to print intricate designs without compromising on strength makes TPU a favorite among designers seeking to innovate. From my experience, friends who have attempted to print with TPU rave about how its unique characteristics open up new avenues for creativity, allowing them to push the boundaries of what their 3D printers can achieve.

Common Uses of TPU 3D Printer Filament

TPU filament has a wide range of applications across various industries. In the automotive sector, it is used to create flexible parts such as seals, grommets, and protective covers. The medical field also benefits from TPU, where it is used for manufacturing patient-specific prosthetics and flexible medical devices. Additionally, the consumer goods industry utilizes TPU to produce durable yet flexible products like footwear, sporting goods, and custom phone cases. Friends of mine who are hobbyists have created everything from custom drone parts to unique toys, showcasing the filament's versatility. The ability to produce low-volume custom parts quickly further cements TPU's role in modern manufacturing and prototyping.

Benefits of Using TPU 3D Printer Filament

The benefits of using TPU filament are numerous. Its versatility allows for a wide range of applications, making it suitable for both functional prototypes and end-use products. The strength of TPU is remarkable; it can withstand significant wear and tear while maintaining its structural integrity. Additionally, TPU is capable of producing complex geometries that would be challenging with more rigid materials, enabling innovative designs that can enhance product performance. Importantly, TPU is often seen as a more sustainable option compared to traditional petroleum-based plastics, as it can be sourced from renewable materials and is recyclable. Friends who have shifted to using TPU in their projects have noted not only the performance benefits but also the positive environmental impact, adding an extra layer of satisfaction to their creative endeavors.

Key Takeaways on TPU 3D Printer Filament

In conclusion, TPU 3D printer filament stands out as a remarkable material in the realm of 3D printing, offering a unique combination of flexibility, durability, and versatility. Its ability to cater to a range of industries—from automotive to medical—demonstrates its importance in modern manufacturing. As we explored, the features and benefits of TPU are compelling reasons for both hobbyists and professionals to consider this filament for their future projects. Whether you're looking to create custom parts, innovative designs, or sustainable products, TPU filament is undoubtedly a material that can elevate your 3D printing experience.